Careers

Why join Standex Engineering Technologies Group?

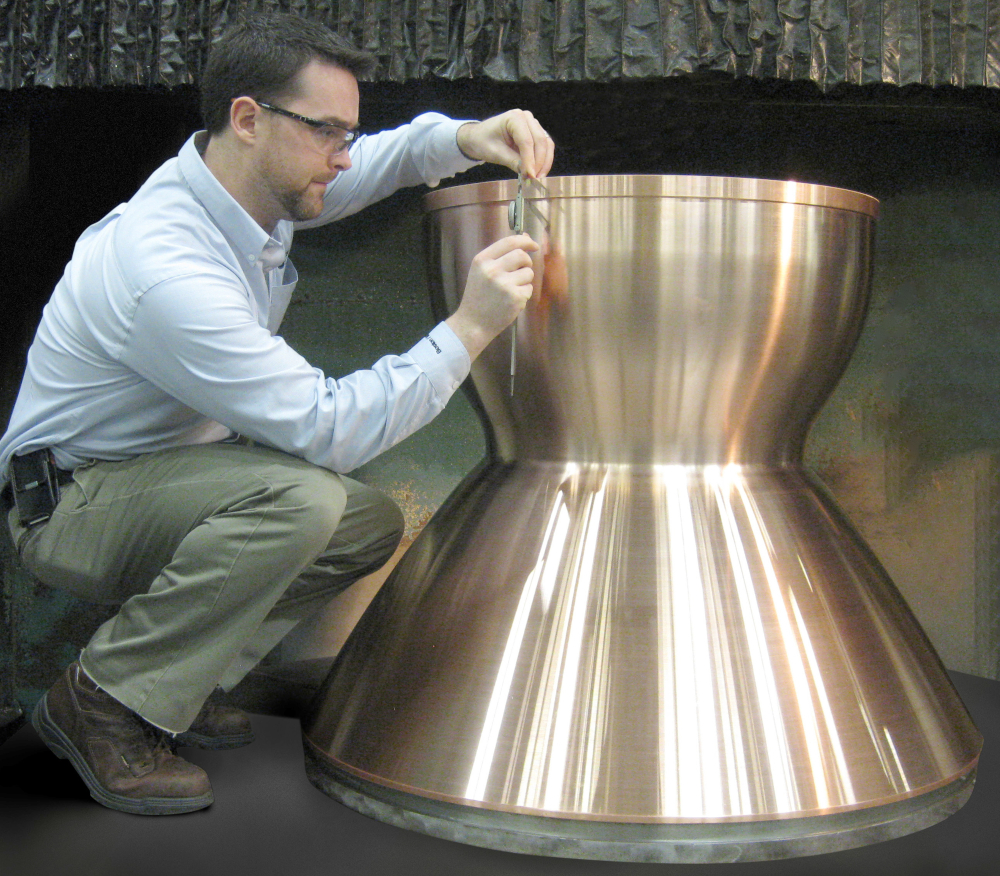

Standex ETG employees see the next generation of rockets launch and say, “I helped create something on that vehicle that helped it travel into space.” For example, they look out the window of an airplane and recognize a solution they supported through development and production. They know other Standex ETG products are keeping troops safe or providing unmatched quality to the medical field.

Our employees work in a dynamic work environment at the leading edge of manufacturing technology. Therefore turning raw material and experience into precision-formed turnkey solutions provides visible signaling of Standex ETG’s value-add to the marketplace we support.

Above all, working for Standex ETG is about taking pride in our solutions. We keep our customers at the forefront of their industries. It’s not rocket science, but there is plenty of rocket component manufacturing in your career with us!

What sets us apart?

Given that we are leading sustainability efforts that result in positive impacts on our employees and communities, we strive for hardworking teammates that agree with our mission. Attracting, developing and retaining exceptional people in an inclusive work environment is vital to ETG’s accomplishments. Cultivating an environment where all employees can reach their greatest career potential is our guarantee. As a part of the Standex ETG team, employees should always feel supported in those efforts. Together we drive efficiency, comprehensive safety practices and employee incentivized plans across all of our facilities.

Our Core Values

In order to fully leverage our resources, unmatched knowledge and expertise in various industries, we work seamlessly across our businesses. It is important to emphasize that the teamwork of all Standex ETG and Spincraft employees allows the group to thrive on providing advanced metal forming solutions to our customers.

Our Leadership Team champions and leads our workforce on seven key values:

- Integrity

- Collaboration

- Customer Focused

- Continuous Improvement

- Quality and Safety

- Innovation

- Employee Engagement

Employee Benefits

Most importantly, we aim to strengthen our workforce by offering a very comprehensive benefits package that includes the following:

- Health Insurance

- HSA & FSA Accounts

- Dental Insurance

- Vision Insurance

- Health Screening & Coaching

- Life & Supplemental Life Insurance

- Critical Illness & Accident Insurance

- Disability Insurance

- Accidental Death & Dismemberment Insurance

- Pension Plan

- 401K Plan with Match

- Employee Stock Purchase Plan

- Maternity Leave

- Military Leave

- Family Medical Leave

- Vacation & Paid Time Off

- Paid Sick Time

- Paid Holidays

- Bereavement Leave

Employee Programs

We recognize that our employees are our most important asset. Because of this, we offer the following employee assistance programs to support you.

- Employee Assistance Program (EAP)

- Tuition Assistance

- Professional Development Training

- Children Scholarship Program

- Charitable Donation Matching Gift Program

Job Boards

Use the links below to explore the current open career opportunities within Standex ETG.

Join Our Team

Our team is made up of honest, hardworking and motivated individuals that take pride in what they do. Check out our openings today and apply to be a part of the team!